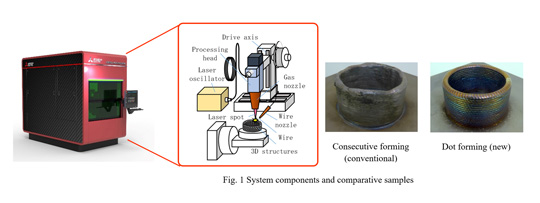

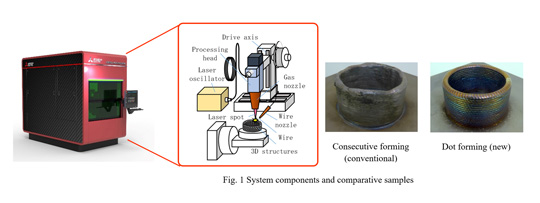

Mitsubishi Electric Corporation (TOKYO: 6503) announced today that it has developed a unique dot forming technology that realizes high-precision shaping by combining laser, computer numerical control (CNC) and computer aided manufacturing CAM technologies in 3D printers. The technology produces high-quality three-dimensional (3D) parts with few voids at high speed, employing a laser wire directed-energy deposition (DED) method, which is an additive-manufacturing process that uses focused thermal energy to fuse materials as they are deposited. Mitsubishi Electric believes that its new technology will raise productivity in a wide range of applications, such as the “near-net” (near-final) shaping of aircraft and automobile parts and build-up repairs.

A three-dimensional metal shaping machine incorporating the new technology will be exhibited for reference at the 29th Japan International Machine Tool Fair (JIMTOF2018), which will be held at the Tokyo Big Sight exhibition complex beginning November 1. Mitsubishi Electric expects to launch a commercial version within the fiscal year ending in March 2021.

A three-dimensional metal shaping machine incorporating the new technology will be exhibited for reference at the 29th Japan International Machine Tool Fair (JIMTOF2018), which will be held at the Tokyo Big Sight exhibition complex beginning November 1. Mitsubishi Electric expects to launch a commercial version within the fiscal year ending in March 2021.

Key Features

| 1) | High-quality 3D parts formed at high speed

|

||||||||

| 2) | Improved shape accuracy through unique dot forming technology

|

||||||||

SOURCE: Mitsubishi Electric Corporation