Toyoda Gosei Co., Ltd. has developed a lightweight plastic material reinforced with fibers that use magnesium hydroxide derived from seawater.

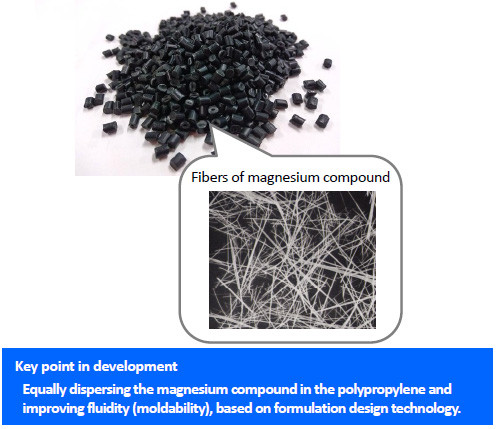

As one part of its efforts for decarbonization, Toyoda Gosei is focusing on making lighter weight products by leveraging its plastic and rubber materials technology. In this newly-developed plastic material, a magnesium compound derived from seawater is mixed as part of the reinforcing material into a general purpose plastic (polypropylene) used in interior and exterior products. The magnesium compound is fibriform, and so provides greater reinforcement than the previous material (talc). As a result, the amount of reinforcing material can be reduced by half, while retaining the same quality as before. This will lead to lighter weight products and contribute to improved environmental performance of vehicles during operation. Another property of the new material is that scratches are less noticeable. This eliminates the need for paint to protect the surface on some products, contributing to a reduction in CO2 during manufacture. *

This technology will be shown at IPF Japan 2023 (International Plastic Fair), held at Makuhari Messe (Chiba, Japan) over five days starting on November 28, 2023.

*In some products, CO2 can be reduced by as much as 70%.

Newly developed plastic reinforced with fiber derived from seawater

Interior product (meter hood) that is about 7% lighter in weight

SOURCE: Toyoda Gosei