Mitsubishi Fuso Truck and Bus Corporation (Headquarters: Kawasaki City, Kanagawa Prefecture, President and CEO: Karl Deppen, hereafter “MFTBC”) will build a test facility for recovering materials from used electric vehicle (EV) batteries at its Kawasaki Plant, in partnership with True 2 Materials Pte. Ltd (Headquarters: Singapore, CEO: Richard Carlow, hereafter: T2M). Starting in 2025, the companies will use the pilot plant to evaluate the reusability of anode, cathode, and electrolyte materials by battery cell makers.

The number of used EV batteries is expected to increase as demand for EVs expands amid global trends towards decarbonization. Used EV batteries can be reused for other purposes as they are, or they can be recycled to procure raw materials and components for other products. Through the tests jointly with T2M, MFTBC will consider a business venture that recycles used batteries from EV trucks, such as its electric light-duty eCanter, and EV passenger cars, into compounds that can be directly used as high-quality blended materials in battery cells.

MFTBC will first consider commercialization in Japan and investigate the possibility of overseas expansion in the future. While batteries account for a significant part of an EV’s cost, MFTBC intends to maximize the value of battery materials by developing effective retreatment processes, and thereby reducing the total cost of EVs. The company aims to eventually create an environment where customers can easily transition to e-mobility options.

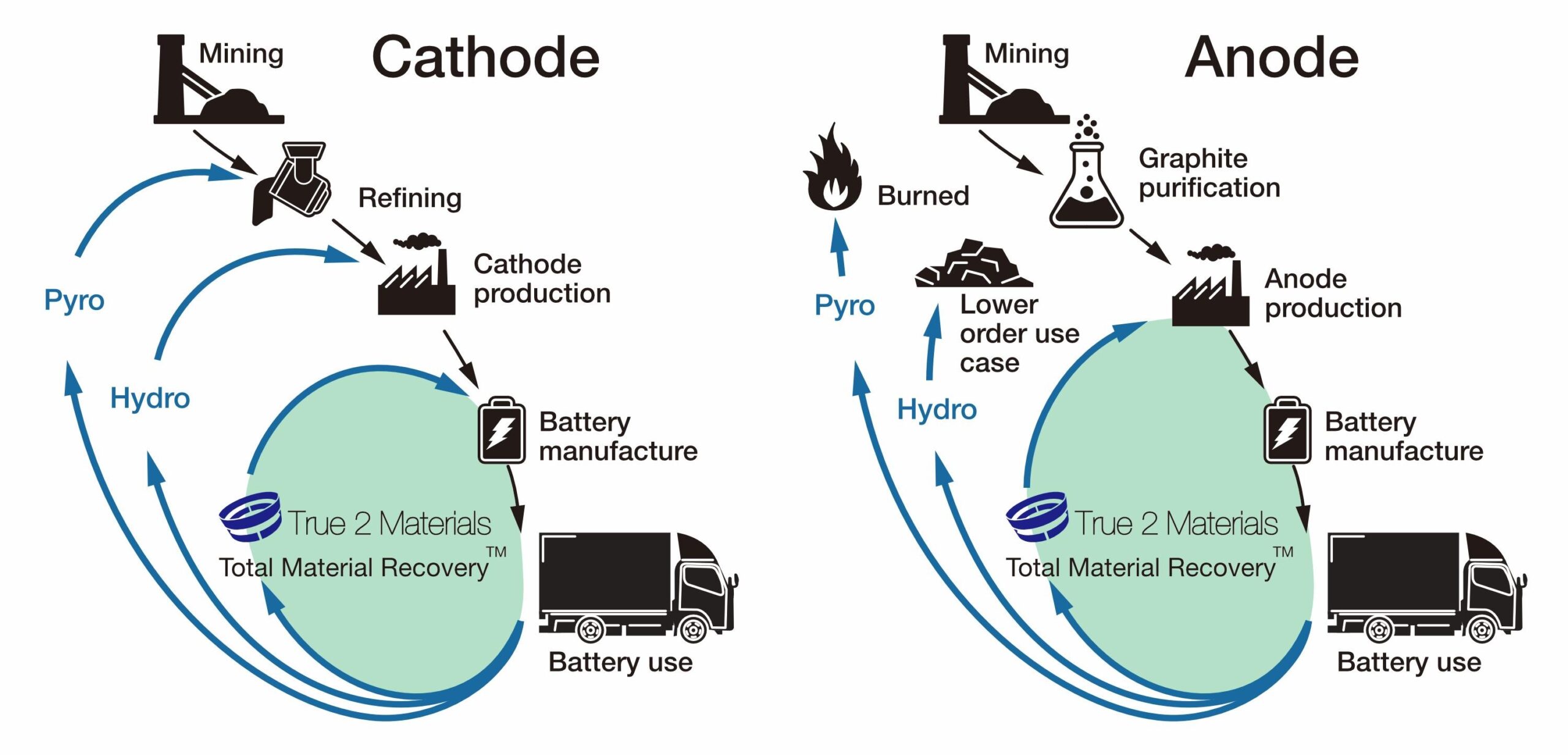

T2M has developed Total Material Recovery (TMR), a technology for processing used and scrap batteries into usable anodes and cathodes while minimizing loss of raw materials and their value and reducing environmental impact. The TMR process uses nano-level molecular techniques and is different from conventional pyrometallurgy and hydrometallurgy battery recycling. The technology allows recovery of up to 99.9% of all EV battery resources, a higher percentage than conventional methods, thereby maximizing battery resource value. This novel process also greatly reduces the amount of CO2 and other emissions, reducing the environmental impact of disassembly processing. In addition, it is expected that the cost of metal processing, which generally accounts for nearly 75% of the cost of the entire recycling process, will be significantly reduced.

This initiative is part of MFTBC’s FUSO eMobility Solutions framework to support customers’ EV shift. MFTBC will continue to develop products and services that contribute to realizing carbon neutrality by 2050.

Cycles of anode and cathode components for EV batteries

SOURCE: Fuso