Black-and-white capsule styling seemingly comes from the future; without a driver’s seat, without a steering wheel, a throttle and a brake, it is really pilotless …

On April 23, in Dongfeng Motor Corporation Technical Center, pilotless minibus Sharing-VAN was very attractive. Here, self-developed automobile engine, lightweight vehicle body structure, hydrogen vehicle, cool concept vehicle … a series of “black technologies” are dazzling, making people exclaim that “the future has come”.

In recent years, DFM has increased its investment in lightweight, electric, intelligent, networked and shared development, and has made some leading achievements in many fields.

Automated driving: Pilotless automobiles during the pandemic have been used in disinfecting “combat”.

Some time ago, in the COVID-19 rehabilitee quarantine, a pilotless minibus drove on an 1.1km ring road to disinfect every morning, afternoon and evening.

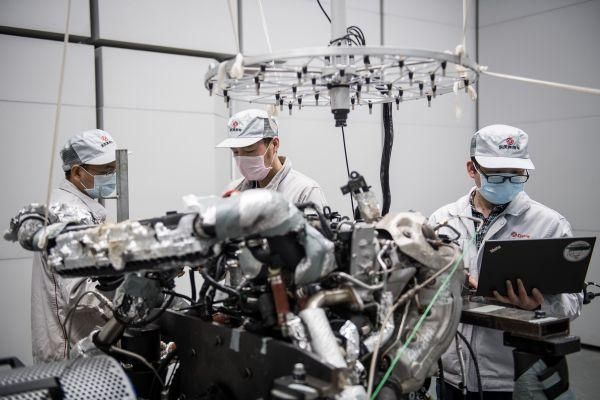

(On April 23, in Dongfeng Motor Corporation Technical Center Engine NVH Laboratory, engineers were commissioning power unit.)

This minibus was equipped with a 16L high-capacity fully-automatic disinfectant sprayer. The sprayer took only 15 minutes to disinfect about 10,000 square meters in a single pass. Its efficiency is obviously higher than manual operation.

This is DFM’s self-developed pilotless minibus Sharing-VAN, equipped with L4-level highly automated driving technology and 5G remote driving technology.

The “brain center” of the disinfecting vehicle is located in dispatching console of 5G Parallel Driving Control Center in Dongfeng Motor Corporation Technical Center, where the anti-pandemic staff must keep in “zero contact” with the infection hazard area.

(Engineers are commissioning robot arm on the production line.)

“Pilotless driving” is a future trend of automobile development. As early as 2013, DFM has started the research into automated automobile technology, and launched 2013 A60 intelligent prototype, 2017 AX7 automated driving 2.0 prototype, Dongfeng 5G remote driving prototype, and Dongfeng Warrior pilotless driving off-road prototype.

In September last year, DFM’s self-developed Robotaxi automated taxi was awarded Wuhan’s first road test license for automated automobile. This vehicle model has automatic pick-up and drop-off, intelligent vehicle infrastructure cooperative systems, vehicle APP reservation, remote operation and maintenance management and other functions, which can effectively improve convenience of transportation.

In terms of individual transportation sector, DFM’s mass-produced vehicle model – Aeolus dazzling vehicle model has L3-level automated driving, which can realize industrially-leading automated driving on expressway / elevated road.

BEV:

Self-brand BEV takes the lead in realizing endurance mileage of 500km.

“If engine is heart of fuel vehicle, electrically-driven powertrain is heart of electric vehicle.” Development of electrically-driven powertrain, as core of electric vehicle, is crucial to development of vehicle.

At present, Dongfeng Motor Corporation Technical Center is researching and developing the third-generation electrically-driven powertrain (BD90 Project), with a 20% increase in power density and a 2% increase in efficiency compared with overseas like products.

(Engineers are checking running conditions of chip mounter.)

Overall progress of the project was delayed one month and a half due to the pandemic. “Currently, the project team uses double-shift system to stretch daily testing time from 8 to 12 hours. Up till now, we have make up 20 days.” said technical director Xu Gang.

Next, this electric drive will be equipped with Dongfeng Aeolus new E70 and other electric vehicle models to enhance their commercial competitiveness.

As early as 2017, DFM formally put forward the strategy of “lightweight, electric, intelligent, networked and shared development”, laid out and reserved many technologies in these areas, which have achieved many results.

(On April 23, in Dongfeng Motor Corporation Technical Center Exhaust Emission Laboratory, engineers were carrying out vehicle test)

For example, lightweight materials have been heavily applied to DFM’s self-developed passenger vehicles, and proportion of application to single vehicle exceeds 60%, much higher than the industry average of 50%.

For another example, a refitted vehicle model of Dongfeng Aeolus E70, with an endurance mileage of 508km, becomes one of the first self-brand BEVs with an endurance mileage of 500km, as well as one of China’s most energy-efficient BEVs.

“In the future, DFM will carry on more practices of ‘lightweight, electric, intelligent, networked and shared development’ to provide users with all-round high-quality automobile products and services.” said relevant person in charge.

SOURCE: DONGFENG