Improved Durability on Rough Roads and Improved Handling “Feel”

NSK Ltd. (NSK; Headquarters: Tokyo, Japan; President and CEO: Norio Otsuka) announced today that it has developed a high durability, high rigidity, slideable intermediate shaft for column-type electronic power steering (EPS) for automobiles in the ever-expanding emerging markets.It provides a superior handling “feel” and improved durability on rough roads.

NSK is targeting 10 billion yen in global annual sales as it expands the application of this product across a wide range of automobiles, mainly in emerging markets.

Development Background

As automobiles have become more commonplace in emerging nations, the application of EPS has also increased in order to improve fuel economy.In these markets, there are still many rough roads, which presents the challenge of improving durability and suppressing the vibration and noise that gets transmitted to the steering wheel.

EPS employs a motor to assist the steering force of drivers as they turn the steering wheel in the direction they wish to go.EPS also transmits that steering force onto the suspension via the intermediate shaft.The intermediate shaft not only transmits the rotational movement (steering angle and steering force), but it also helps to absorb deflection of the vehicle body by expanding and contracting.

Product Features

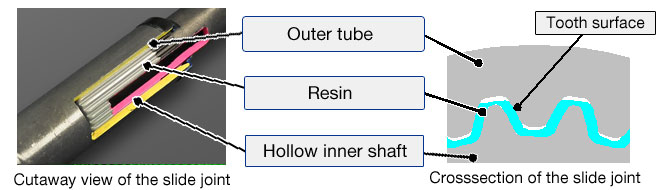

(1) Improved Durability in the Slide Joint.By increasing the size of the slide joint and the number of meshing teeth, NSK has reduced the amount of force exerted on the tooth surface, thereby improving wear resistance.

(2) Improved Handling “Feel”. (Increased Rigidity of the Slide Joint)By increasing the size of the slide joint, increasing the number of meshing teeth and increasing the size of the inner shaft, NSK has increased the rigidity. In addition, as a world’s first for high output column-type EPS, NSK hollowed out the inner shaft to achieve weight reduction while maintaining the same size as the conventional part.

(3) Suppressed Handled Vibration. (Improved Slide Characteristics in the Slide Joint)By applying an optimum thickness of resin coating on the inner shaft surface and applying grease that has superior lubrication performance, NSK has reduced the wear of the slide joint. Additionally, by increasing the size of the slide joint and the number of meshing teeth, NSK has reduced the amount of force exerted on each tooth surface, thereby greatly reducing slide resistance. In this way, the intermediate shaft can slide more smoothly for better vibration absorption and a reduction in the amount of unpleasant vibration and noise that can get transmitted from the road to the steering wheel when driving on rough roads.

Product Benefits

Development of an EPS Intermediate Shaft That is Optimum for Automobiles in Emerging Markets.

This product not only features improved durability on rough roads, but it also makes for a handling “feel” that allows the driver to “be as one with their automobile.” NSK will introduce this product in emerging nations and then expand application to the global automobile market.